A formulation of methylammounium iodide (MAI), PbCl2 and PbI2 at a molar ratio of 1:1:4 (PbCl2:PbI2:MAI) in a DMF solvent. On processing, I201 ink can be used to create a CH3NH3PbI3-xClx perovskite film. The process recipe for I201 is optimised for glove box processing under a nitrogen atmosphere.

I201 perovskite ink is divided into 10 lots of 0.5 ml. We have found this quantity to be sufficient for 10 individual experiments (approximately 160 device substrates).

Datasheet

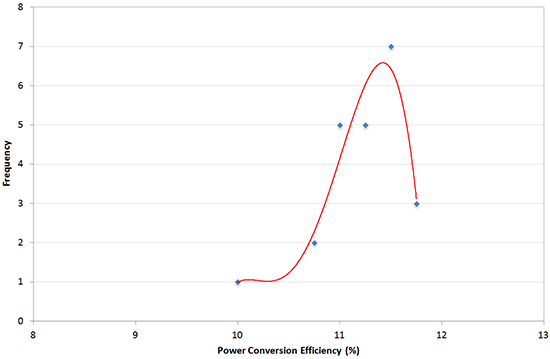

We have specially formulated I201 Perovskite Ink in our laboratories to make it suitable for deposition by spin-coating. It is based on similar ink formulations used in references [1]. This ink is designed to be used with a bottom ITO/PEDOT:PSS anode and a top PC70BM/Ca/Al cathode, with PV devices fabricated with an average / peak power conversion efficiency (PCE) of (11.2% ± 0.4)% / 11.8%. This performance level is in accord with other literature reports using similar ink formulations where PCEs of approximately 11.5% have been demonstrated [1]. A full process recipe comes with the ink, which is ready to use after heating for a short time.

References (please note that Ossila has no formal connection to any of the authors or institutions in these references):

- Reproducible One-Step Fabrication of Compact MAPbI3-xClx Thin Films Derived from Mixed-Lead-Halide Precursors, D. Wang et al., Chem. Mater., 26, 7145-7150 (2014) DOI: 10.1021/cm5037869

Specifications

Perovskite precursor ink formulation: Ink I201 is based on a mixture of methylammonium iodide (MAI), lead chloride (PbCl2) and lead iodide (PbI2) at a molar ratio (PbCl2:PbI2:MAI) of 1:1:4 dissolved in anhydrous DMF (dimethylformamide).

| Compound | Purity | Molar Ratio |

|---|---|---|

| MAI | > 99% (as measured by Elemental Analysis) | 1 |

| PbCl2 | 99.999% | 1 |

| PbI2 | 99.999% | 4 |

| DMF | 99.8% | n/a |

Now selling bulk orders of 30ml with a 25% discount over our standard order sizes.

Usage Details

Fabrication Routine for Perovskite Precursor Ink I201

Glass / ITO / PEDOT:PSS / CH3NH3PbI3-xClx / PC70BM / Ca / Al

For complete step-by-step instructions please see our Full Perovskite Solar Cells Fabrication Video or written fabrication guide. Please note, however, that the routine in these full guides differs slightly to the optimised routine for the I201, which is designed to be processed in a nitrogen filled glove box.

The summary below outlines the key steps required when processing I201 ink. You can also download this summary as a PDF in order to print and laminate it for us in a clean room.

1. Substrate clean (in air):

- Sonicate ITO substrates for 5 minutes in hot (70°C) 1% Hellmanex

- Dump-rinse substrates twice in boiling, deionised (DI) water

- Sonicate for 5 mins in IPA. Dump-rinse twice in boiling DI water

- Dry the substrates with nitrogen gun

- Bake the substrates on a hotplate at 120°C.

2. PEDOT:PSS anode preparation (in air):

- Filter AI 4083 PEDOT:PSS using a 0.45 µm PES filter

- Dispense 35 µl of the filtered PEDOT:PSS solution onto the heated ITO substrate spinning at 6000 rpm for 30s

- Place substrate onto a hotplate at 120°C

- After all ITO substrates have been coated with a PEDOT:PSS layer, transfer all to a nitrogen-filled glove box and place onto a hotplate at 120°C for 20-30 mins

- Remove the substrates from the hotplate and allow to cool at room temperature.

3. Perovskite deposition (in nitrogen glove box):

- Heat I201 ink for 2 hours at 70°C and then cool to room temperature

- Place the ITO coated substrate (at room temperature) onto the spin-coater and spin the substrate at 4000 rpm (for 30s)

- Dynamically dispense 30 µl of I201 ink

- Place substrate back onto the hotplate (in the glove box) at 80°C

- Once all substrates have been coated, anneal for 90 mins

- After 90 mins, use a cleaning swab dipped in a small amount of DMF solvent to wipe the cathode stripe clean

- After cleaning, anneal for an addition 20-30 mins at 80°C to remove any residual DMF solvent

- After this time, remove substrates from the hotplate and cool to room temperature.

4. PC70BM deposition (in nitrogen glove box):

- Prepare a solution of PC70BM at 50 mg / ml in chlorobenzene and stir for 3 to 5 hours

- Place perovskite coated substrate onto the spin-coater and spin at 1000 rpm

- Dispense 20 µl of PC70BM solution onto the substrate (while spinning) and spin for a total time of 30s.

5. Cathode deposition:

- Thermally evaporate a calcium/aluminium cathode (5 and 100 nm respectively) through shadow-mask

- Encapsulate devices using a glass coverslip and encapsulation epoxy

- Expose to UV radiation (350 nm) for 30 mins to cure epoxy.

Perovskite Photovoltaic Device Performance

Below are device characteristics for our best pixel fabricated using the I201 fabrication recipe described above.

JV curves demonstrate the hysteresis observed from the device and include device metrics for both forward and reverse sweeps. The pixel presented (from a reverse sweep) had a power conversion efficiency of 11.8%, a Voc of 0.91 V, a FF of 79% and a Jsc of -16.5 mA/cm2.

To the best of our knowledge the technical information provided here is accurate. However, Ossila assume no liability for the accuracy of this information. The values provided here are typical at the time of manufacture and may vary over time and from batch to batch.

ebiomall.com

>

>

>

>

>

>

>

>

>

>

>

>

耗材:滤纸、PVDF膜或NC膜、乳胶手套等

仪器:电泳仪、电转槽、摇床、制冰机(电转时需冰浴)等

原理简介:

本试剂盒采用改进SDS-碱裂解法裂解细胞,离心吸附柱内的硅基质膜在高盐,低pH值状态下选择性地结合溶液中的质粒DNA,再通过去蛋白液和漂洗液将杂质和其它细菌成分去除,最后低盐,高pH值的洗脱缓冲液将纯净质粒DNA从硅基质膜上洗脱。

注意事项:

◆ 第一次使用时,将试剂盒所带全部的RNase A加入溶液P1后(终浓度100ug/ml)置于4℃保存。如果溶液P1中RNase A失活,提取的质粒可能会有混杂有微量RNA残留, 这时可在溶液P1中补加RNase A即可。

◆ 第一次使用前请先在15ml漂洗液WB中加入45ml无水乙醇,加入后请及时在方框打钩标记已加入乙醇,以免多次加入!

◆ 温度低时溶液P2中SDS可能会出现浑浊或者析出沉淀,可在37℃水浴加热几分钟,即可恢复澄清,不要剧烈摇晃,以免形成过量的泡沫。

◆ 避免试剂长时间暴露于空气中产生挥发、氧化、pH值变化,各溶液使用后应及时盖紧盖子。

试剂盒特点:

◆ 产量高---一次提取高达30ug以上的质粒。

◆ 纯度高---OD260/OD280一般为1.80~1.85本试剂盒提取的质粒纯度好,能充分保证测序所需要的读长(用于ABI3730测序一般可达1000bp有效读长)。

◆ 快速,方便,不需要使用有毒的苯酚,氯仿等试剂,也不需要乙醇沉淀。

提示

BIOTEKE的质粒提取试剂盒既适用于革兰氏阴性菌中质粒的提取,同时也可从革兰氏阳性菌中提取质粒。由于革兰氏阳性菌外被一层较厚的细胞壁,会严重阻碍细菌细胞的裂解,因此必须在裂解细胞前破除,方法如下:

收集适量的菌体,加入250ul溶液P2,充分悬浮菌液,加入溶菌酶使其终浓度在10-20mg/ml左右在37℃处理30分钟左右。加入溶菌酶的浓度和处理的时间可根据不同的菌主和具体实验条件进行调整。

原液分装。抗体孵育之前稀释。

做WB的浓度不一定需要很高的。可以设置简单梯度1:200;1:500;1:1000 。看结果再优化

1. 使用预染 Marker,不过分子量不是特别准;

2. 所使用的 Marker 条带与待测蛋白质带有相同的抗原表位,比如都带有 His 融合标签;

3. 可以使用普通的 Marker 转膜使用 丽春红 等染色,然后在膜上标记出 Marker 各条带的位置。